AeroNet has launched its innovative ETSO C90d Certified Air Cargo Pallet, featuring a Removable Seat Track, set to transform unit load device (ULD) maintenance and significantly cut costs and repair times for users and maintenance, repair, and overhaul (MRO) operations. Drawing on 20 years of experience in MRO, AeroNet has developed this solution to tackle the persistent issues of time-consuming and expensive repairs associated with air cargo pallets.

For airlines and ULD lessors, ensuring an aircraft’s operational readiness is critical. AeroNet’s Removable Seat Track simplifies repairs by enabling operators to replace only the damaged section, thereby eliminating the need for costly full base extrusion replacements. This innovation translates to reduced downtime and costs, ensuring that ULDs are available promptly for operations.

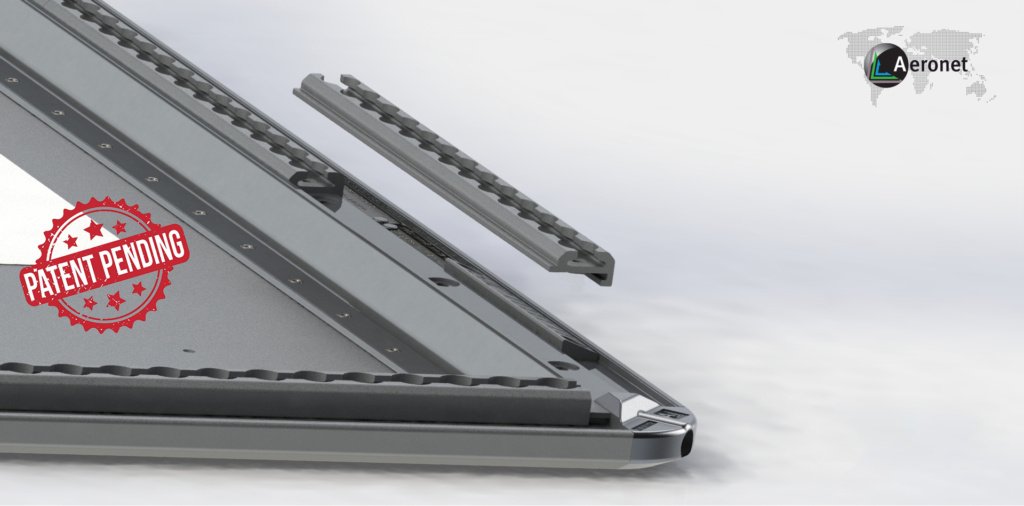

The new design allows for rapid repairs; operators can fix a damaged Seat Track by removing just three rivets, retaining the existing base extrusion. This process cuts repair time from 45 minutes to just five, enhancing turnaround times (TAT) and productivity while minimising operational disruptions.

Additionally, replacing corner parts is now streamlined, requiring only one screw instead of multiple rivets, which simplifies maintenance tasks even further. The compact design of the Removable Seat Track, measuring 13 inches (330 mm), also leads to reductions in shipping and storage costs, as it occupies less space compared to full base extrusions.

Built with robust materials to withstand demanding conditions, AeroNet’s Certified Air Cargo Pallet promises long-term reliability, making it a wise investment. With this ground-breaking solution, AeroNet is poised to redefine efficiency, safety, and cost savings in the ULD sector.